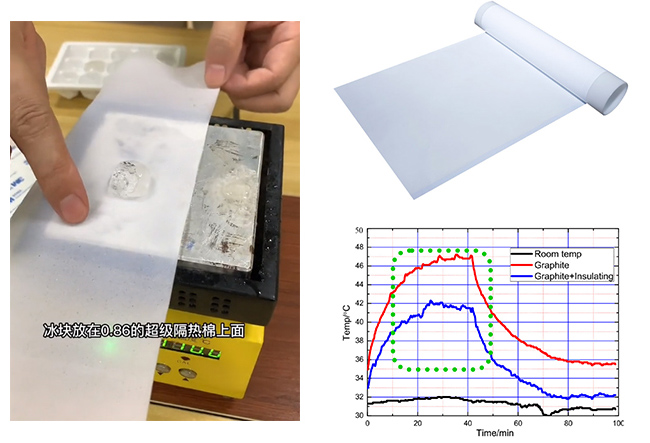

Porous vacuum silicon thermal insulation film is a new type of thermal insulation material with cross-linked sheet structure made of medium and high molecular weight skeleton materials and nano-porous vacuum silicon stones. The pore size of nano-porous vacuum silicon stones is 10~40nm, which is smaller than the average free path of air molecules (68nm), and with a porosity of over 97% and a density as low as below 0.03g/ml, it can achieve a near-vacuum effect. Therefore, molecules inside the pores do not collide with each other, resulting in ultra-high thermal insulation performance.

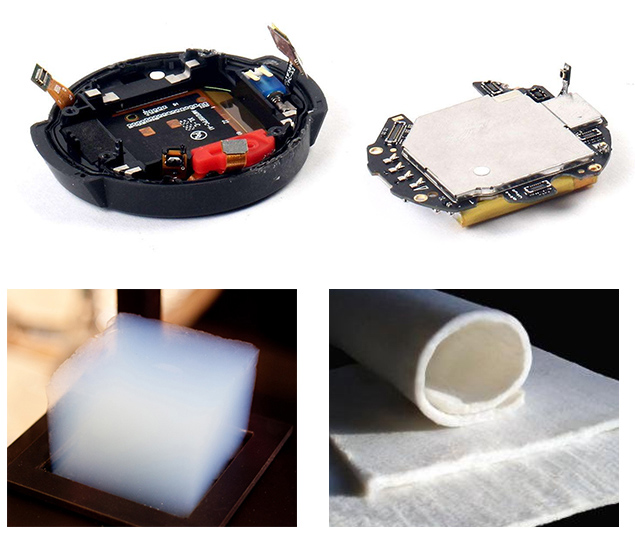

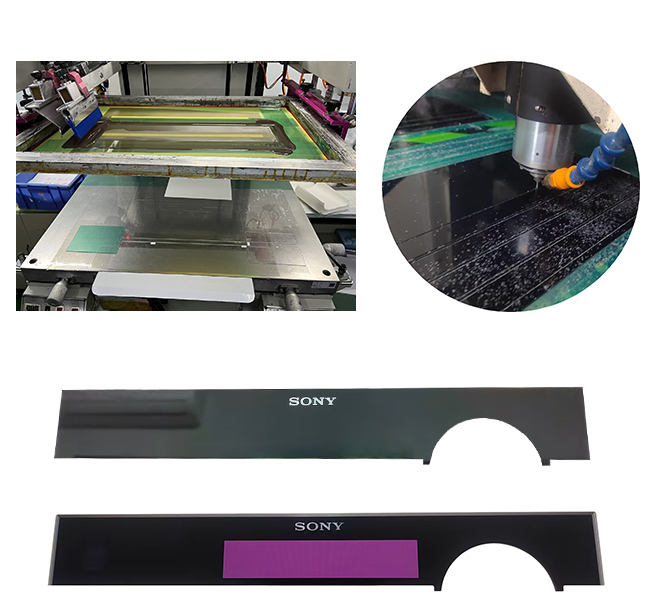

Porous vacuum silicon thermal insulation film is a flexible thermal insulation sheet combining porous vacuum silicon stone materials with polymer skeleton materials through a vacuum cross-linking vaporization and high-pressure drying preparation process. It has a porous structure with a uniform surface and a thermal conductivity as low as 0.014W/(m·K). It also has excellent properties such as hydrophobicity, flame retardancy, insulation, and environmental protection. It solves the problem of thermal insulation and heat preservation in narrow spaces for electronic products and further improves human comfort. Compared with traditional thermal insulation materials, it has a lower thermal conductivity and is very suitable for use in electronic products, such as aerospace, smart handheld devices, smart wearables, e-cigarettes, wireless chargers, power supplies, small appliances, and thermal insulation and heat preservation for large equipment.